Understanding the Concept of Stop Ops

Have you ever come across the term “stop ops” and wondered what it means? In this article, we will delve into the various dimensions of stop ops, providing you with a comprehensive understanding of its significance and applications.

What is Stop Ops?

Stop ops, in simple terms, refer to a temporary halt or suspension of operations. It is a term commonly used in various industries, including construction, manufacturing, and information technology. The purpose of implementing stop ops is to address specific issues or carry out maintenance activities that require the temporary shutdown of operations.

Reasons for Implementing Stop Ops

There are several reasons why organizations may decide to implement stop ops. Here are some of the most common ones:

| Reason | Description |

|---|---|

| Equipment Maintenance | Regular maintenance of equipment is crucial to ensure its optimal performance. Stop ops allow for scheduled maintenance activities to be carried out without disrupting ongoing operations. |

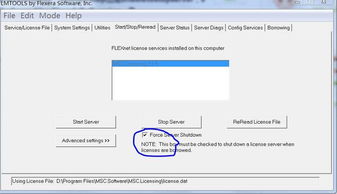

| System Upgrades | Upgrading systems and software is essential for keeping up with technological advancements. Stop ops provide the opportunity to implement these upgrades without affecting the organization’s productivity. |

| Addressing Safety Concerns | Immediate stop ops may be required to address safety concerns, such as equipment malfunctions or potential hazards that could pose risks to employees or the public. |

| Compliance with Regulations | Organizations must comply with various regulations and standards. Stop ops may be necessary to ensure compliance with these requirements. |

Planning and Executing Stop Ops

Planning and executing stop ops effectively is crucial to minimize disruptions and ensure a smooth transition. Here are some key steps to consider:

-

Identify the purpose and scope of the stop ops.

-

Develop a detailed plan, including timelines, responsibilities, and communication strategies.

-

Notify all stakeholders, including employees, customers, and suppliers, about the planned stop ops.

-

Ensure that all necessary resources, such as equipment, materials, and personnel, are available for the maintenance or upgrade activities.

-

Monitor the progress of the stop ops and make adjustments as needed.

Challenges and Considerations

Implementing stop ops can come with its own set of challenges. Here are some of the key considerations:

-

Communication: Ensuring clear and timely communication with all stakeholders is crucial to manage expectations and minimize disruptions.

-

Resource Allocation: Proper allocation of resources, including personnel and equipment, is essential to carry out the planned activities efficiently.

-

Contingency Planning: Having a contingency plan in place can help address unexpected issues that may arise during the stop ops.

-

Cost Management: Stop ops can be costly, so it is important to manage the associated expenses effectively.

Benefits of Stop Ops

Despite the challenges, implementing stop ops can bring several benefits to organizations:

-

Improved Equipment Performance: Regular maintenance and upgrades can enhance the performance and lifespan of equipment.

-

Enhanced Safety: Addressing safety concerns and ensuring compliance with regulations can create a safer working environment.

-

Increased Productivity: By minimizing disruptions and addressing issues proactively, organizations can maintain or even improve their productivity levels.

-

Cost Savings: Proper maintenance and upgrades can help reduce long-term costs associated with equipment breakdowns and repairs.

Conclusion

Stop ops are an essential aspect of maintaining and improving operations in various industries. By understanding the reasons, planning, and executing stop ops effectively, organizations can minimize disruptions, enhance safety, and achieve long-term benefits.