Designing a PID Controller Using Operational Amplifiers: A Detailed Guide

When it comes to controlling processes in various industries, a PID (Proportional-Integral-Derivative) controller is often the go-to solution. This controller, which uses operational amplifiers (op-amps) as its core component, has been widely employed due to its simplicity and effectiveness. In this article, we will delve into the intricacies of designing a PID controller using op-amps, providing you with a comprehensive understanding of the process.

Understanding PID Controllers

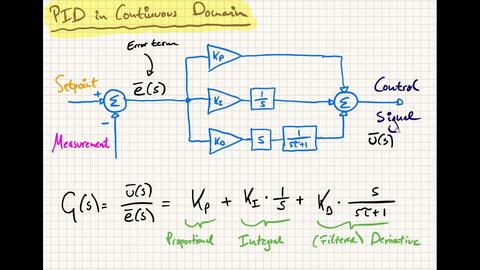

A PID controller is a feedback controller that calculates an error signal by comparing the desired setpoint with the actual process variable. The controller then adjusts the control signal based on the proportional, integral, and derivative terms of the error signal. These terms help in minimizing the error and achieving the desired output.

The proportional term (P) is directly proportional to the error, the integral term (I) accumulates the error over time, and the derivative term (D) predicts the future error based on the rate of change of the error. By adjusting the gains of these terms, the controller can be tuned to achieve the desired response.

Components of a PID Controller

A PID controller typically consists of three main components: the proportional controller, the integral controller, and the derivative controller. Each of these components is designed using op-amps and plays a crucial role in the overall performance of the controller.

The proportional controller amplifies the error signal based on the proportional gain (Kp). The integral controller integrates the error signal over time to eliminate steady-state errors. The derivative controller predicts the future error based on the rate of change of the error, which helps in reducing overshoot and settling time.

Designing the Proportional Controller

The proportional controller is the simplest of the three components. It consists of an op-amp, a resistor (R1), and a capacitor (C1). The error signal is applied to the inverting input of the op-amp, and the output is taken from the non-inverting input.

The gain of the proportional controller is determined by the ratio of R1 to the feedback resistor (Rf). The formula for the gain is given by Kp = Rf / R1. By adjusting the values of R1 and Rf, you can control the proportional gain of the controller.

Designing the Integral Controller

The integral controller is designed using an op-amp, a resistor (R2), and a capacitor (C2). The error signal is applied to the inverting input of the op-amp, and the output is taken from the non-inverting input.

The integral gain (Ki) is determined by the ratio of R2 to the feedback resistor (Rf). The formula for the gain is given by Ki = Rf / R2. By adjusting the values of R2 and Rf, you can control the integral gain of the controller.

Designing the Derivative Controller

The derivative controller is designed using an op-amp, a resistor (R3), and a capacitor (C3). The error signal is applied to the inverting input of the op-amp, and the output is taken from the non-inverting input.

The derivative gain (Kd) is determined by the ratio of R3 to the feedback resistor (Rf). The formula for the gain is given by Kd = Rf / R3. By adjusting the values of R3 and Rf, you can control the derivative gain of the controller.

Combining the Components

Once the individual components are designed, they need to be combined to form the complete PID controller. This is done by connecting the outputs of the proportional, integral, and derivative controllers to the summing junction of the op-amp.

The summing junction is designed using an op-amp, a resistor (R4), and a capacitor (C4). The output of the proportional controller is connected to the inverting input of the op-amp, and the output of the integral and derivative controllers are connected to the non-inverting input.

The gain of the summing junction is determined by the ratio of R4 to the feedback resistor (Rf). The formula for the gain is given by Ks = Rf / R4. By adjusting the values of R4 and Rf, you can control the overall gain of the PID controller.

Testing and Tuning

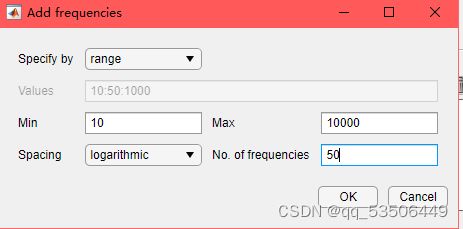

After designing the PID controller, it is essential to test and tune it to ensure optimal performance. This can be done by applying different input signals to the controller and observing the output response.

function pinIt() { var e = document.createElement('script'); e.setAttribute('type','text/javascript'); e.setAttribute('charset','UTF-8'); e.setAttribute('src','https://assets.pinterest.com/js/pinmarklet.js?r='+Math.random()*99999999); document.body.appendChild(e); }